Finite Element Analysis 101

What on earth is Finite Element Analysis?

Finite element analysis (or ‘FEA’) is a technology that allows you to analyse the performance of a structure using a computer. It can answer the question ‘will my boat break?‘.

[It truth it’s a broad domain of mathematical methods that allows one to solve a wide range of problems beyond structures including computational fluid dynamics (CFD) but we’ll stick to the structural side in this post. We’ll cover CFD later!].

Finite what?

The name just describes what’s going on in the mathematics of the solution; it analyses a complex, unknown structural system, by breaking the problem down into a small (finite) number of known subsystems (elements). It imagines a complex structure to be made of a collection of simpler components.

You lost me at finite.

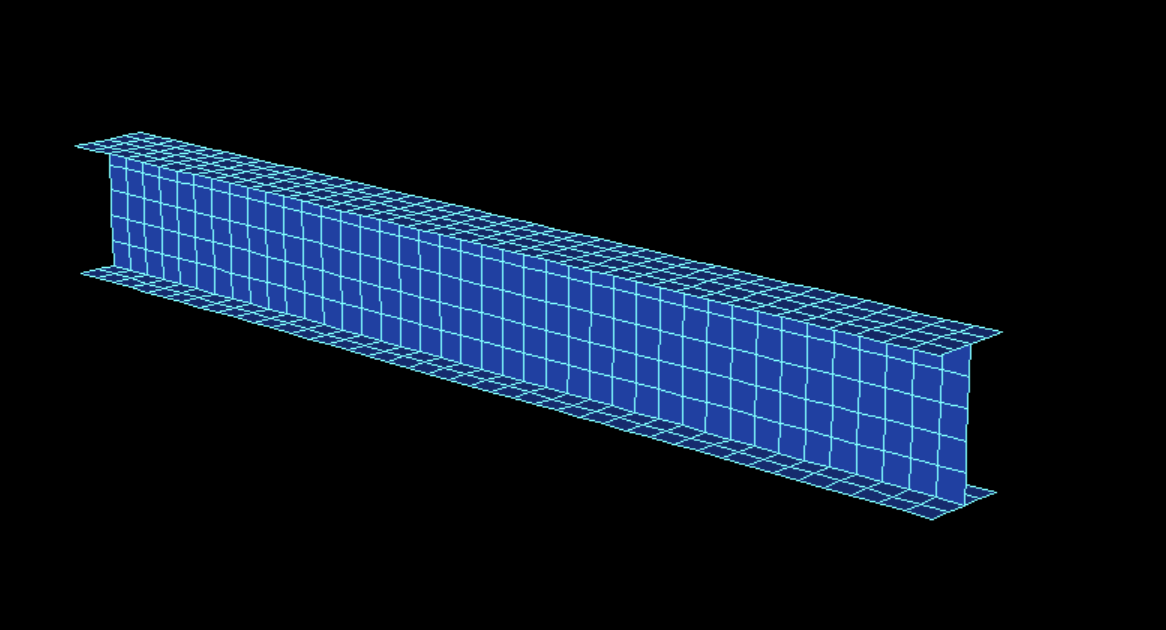

It’s easier to understand with an example or two. Let’s look at a simple ‘I’ beam, supported at one end. [side note: there are different approaches within the discipline of FEA to analysing a structure. For example one can model a structure using ‘elements that represent beams, surfaces or solids (among many others!). Here we’ll be using surface (‘shell’) elements.]

Our beam, supported at the wall.

Our beam, represented as a finite number (520 to be precise) of elements.

Stress distribution map.

The magic of FEA, is that once you know how a single element behaves, it’s possible to work out how a group of them behave when stuck together. The image to the right shows the amount of stress in our beam. Red represents high stress, blue is low.

This is a simple example that most students could solve on the back of a beer coaster. FEA becomes a crucial tool when the structural system becomes more complex, such as in the global structure of a yacht, crane foundations, inertial loads on mast structures, mooring loads, superstructure lifts, localised slamming loads etc etc.

What are the risks?

Unfortunately, it’s not all plain sailing. FEA is also very capable at telling you the incorrect result, and incorrect results can be hard to spot.

Many factors influence whether or not the result that the analysis gives is correct. Real-world boundary conditions can be hard to model mathematically, mesh size, type and aspect ratio all have an effect on the results. The loads applied to the system can be complex and hard to reduce to FEA-friendly inputs.

Multiply these difficulties with the inevitable time constraints of designing to deadlines and it only gets harder.

We have seen complete structural analyses brought unstuck by poor modelling technique. Thoroughness and experience is critical.

The wrap

FEA is a vital tool for understanding how loads move through a complex structure. Like all powerful tools, it requires experienced and judicious use.

Let Elan help your design succeed.